Apr

7

How Machine Vision Technology is Revolutionizing Packaging Quality Control

The Packaging Problem No One Talks About

Every packaging quality control line manager has felt it — that tension when a quality issue slips through. Maybe it’s a leaky seal, a skewed label, a deformed bottle. One defect can trigger customer complaints, product recalls, or halted production.

Every packaging quality control line manager has felt it — that tension when a quality issue slips through. Maybe it’s a leaky seal, a skewed label, a deformed bottle. One defect can trigger customer complaints, product recalls, or halted production.

The old approach? Manual inspection teams trying to keep up with high-speed lines, relying on subjective human judgment. Not scalable. Not reliable. Definitely not future-proof.

Now enter: Machine Vision.

What Is Machine Vision in Packaging?

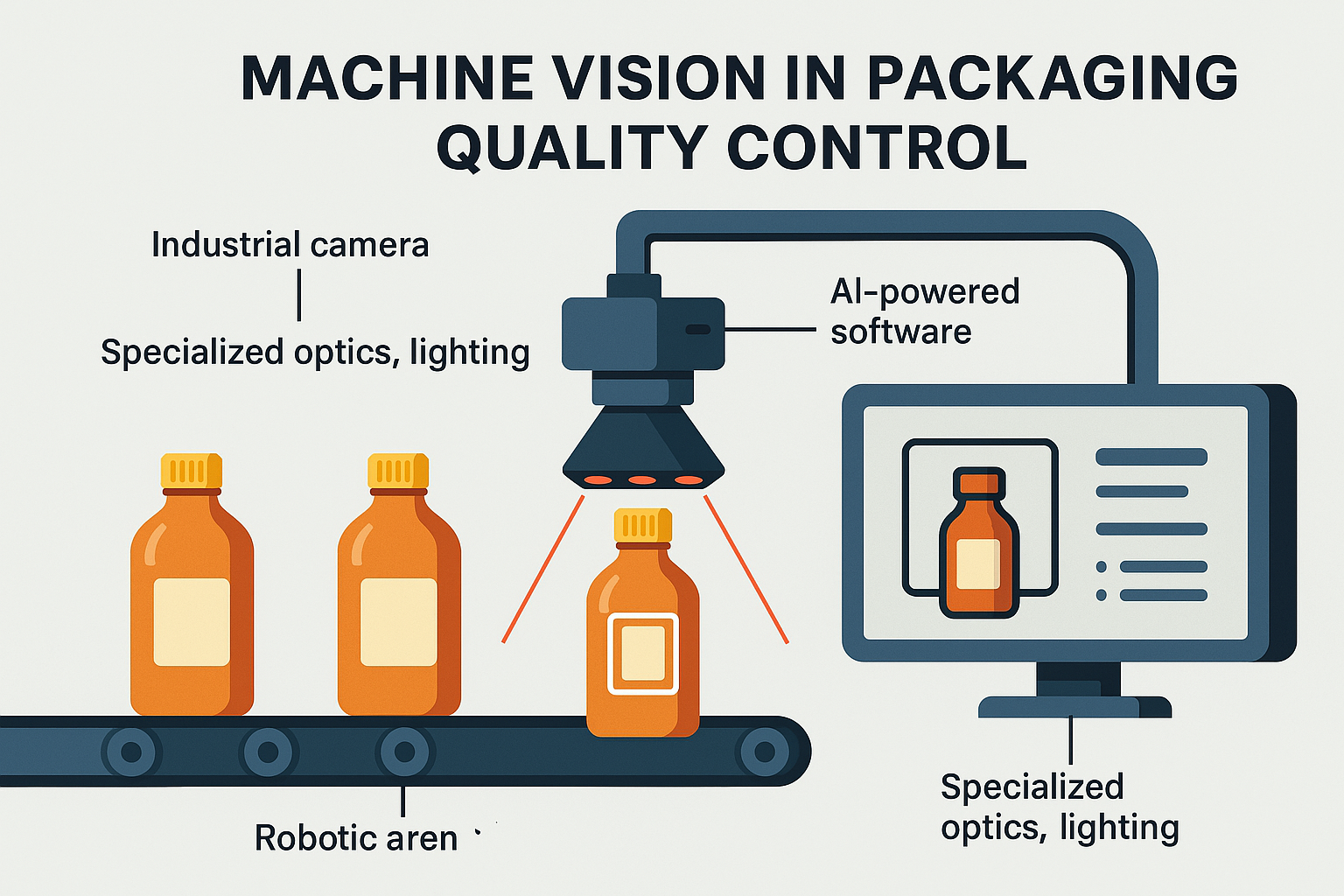

Machine Vision uses industrial cameras, specialized optics, lighting, and AI-powered software to capture, analyze, and inspect packaging components in real-time.

Think of it as a robotic eye with a photographic memory and zero fatigue. It doesn’t blink, doesn’t miss a bottle, and never gets distracted.

How It’s Changing the Game in Quality Control in packaging quality control

- 100% Inline Inspection — Every Unit Counts

Forget sampling. Machine vision systems inspect each and every product on the conveyor, spotting defects within milliseconds.

- High-speed imaging (up to 11,000 bottles/hour)

- Zero downtime detection

- Instant rejection of faulty units

This turns your QA process from reactive to preventive.

- Unmatched Accuracy — Down to Microns

From neck flash in HDPE bottles to invisible pinholes in pharma packaging, machine vision detects what the human eye simply can’t.

- Dimensional accuracy (tolerance < 50 µm)

- Defect detection across sealing surface, threads, caps, labels, and more

- AI/ML classification to reduce false positives

- Standardization Across Shifts & Factories

Human inspection varies by shift, location, and even mood. Machine vision? Repeatable. Scalable. Auditable.

- Perfect for multi-location manufacturers

- Maintains consistent QC no matter who’s operating the machine

- Complies with 21 CFR Part 11 / GMP / ISO 9001 quality norms

- Fast ROI – Pays for Itself

Customers using Optomech’s BIS-XL or ISIVS systems often see returns in under 12 months:

- Fewer customer returns

- Less downtime

- Reduced labor costs

- Increased production speed

- Better audit scores

Real-World Packaging Defects That Machine Vision Solves

| Area | Defects Detected |

| Bottle Neck | Short shot, oval neck, foreign particles, thread damage |

| Cap | Misaligned, missing, tilted, wrong color |

| Label | Misplaced, skewed, unreadable barcodes |

| Sealing | Improper induction sealing, missing liner |

| Body/Base | Holes, dents, warping, surface contamination |

The Future: AI + Vision = Smarter Decisions

Modern systems now include AI-based defect classification:

- Not just detecting “something’s wrong”

- But also classifying what the defect is (flash, burn mark, contamination, etc.)

- Reducing unnecessary rejections

- Auto-sorting for rework vs scra

Optomech’s Vision Systems: Built for Indian Manufacturing packaging quality control

We’ve worked with top packaging manufacturers across pharma, FMCG, and cosmetics, delivering:

- Customizable inspection heads (based on bottle size/shape)

- Plug & play systems with quick changeover for multi-product lines

- 24/7 service + online support

- Data logging for audit compliance

Some of our flagship systems:

- BIS-XL for HDPE/PET/PP bottles

- ISIVS for induction seal verification

- CIS-XL for cap defect detection

- IML Label Inspector for In-Mould Label validation

Bottom Line

Machine Vision isn’t a luxury anymore. It’s mission-critical for packaging lines that want to:

- Reduce human error

- Increase throughput

- Maintain brand integrity

- Pass audits with confidence

- Export to global markets with zero-defect packaging

Want to see it in action?

Let’s set up a free demo using your own sample bottles or containers.

Reach us at sales@optomech.in

Or visit www.optomech.in for case studies and product videos.